In daily life, we often use a variety of tools, and screwdrivers are among the most common. However, their manufacturing process is a precise and complex craft. Today, let’s unveil the production process of screwdriver bits and discover the secrets behind it.

Screwdrivers are common tools we often use in daily life, but the process behind their production is a precise and intricate one. Today, let’s unveil the manufacturing process of screwdriver bits and explore the secrets within. If you’re curious about the story behind our brand, feel free to read more on UFTOOLS’ story page.

Raw Material Testing

The production of screwdriver bits starts with the selection of raw materials. Through rigorous testing, we ensure that the selected materials meet high standards of quality and stability. Tests include chemical composition, hardness, metallographic structure, mechanical performance, and corrosion resistance — all essential to lay a solid foundation for the following processes.

Material Cutting

With high-quality raw materials confirmed, precision material cutting follows. Using advanced cutting equipment ensures every piece is cut with accurate dimensions and precision.

CNC Chamfering

CNC chamfering uses advanced CNC machines to precisely chamfer the cut components according to design specifications.

Turning and Milling the Head

The head of the screwdriver bit is precisely machined using high-precision lathes and milling machines. This step ensures the bit’s shape, size, and angle meet the design requirements, laying a strong foundation for subsequent processes.

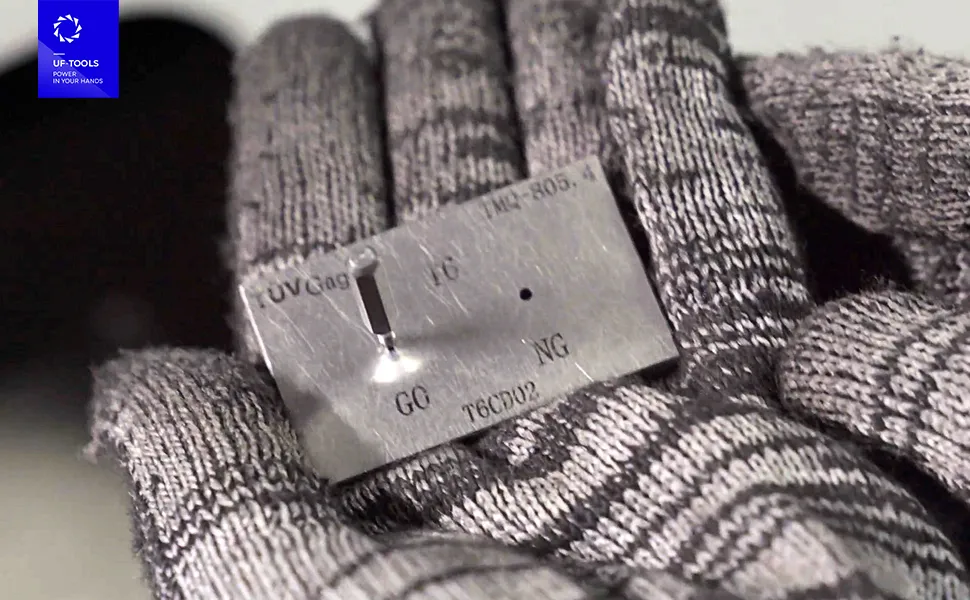

Gauge Measurement

During production, ensuring dimensional accuracy is critical. High-precision gauges are used to carefully measure each bit, ensuring geometric dimensions meet design specifications and guaranteeing consistency and stability.

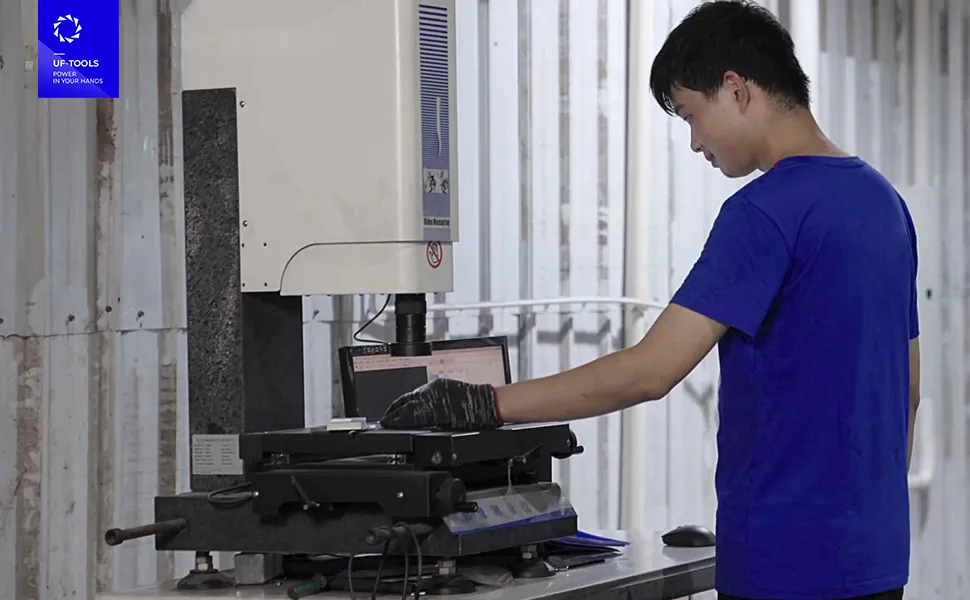

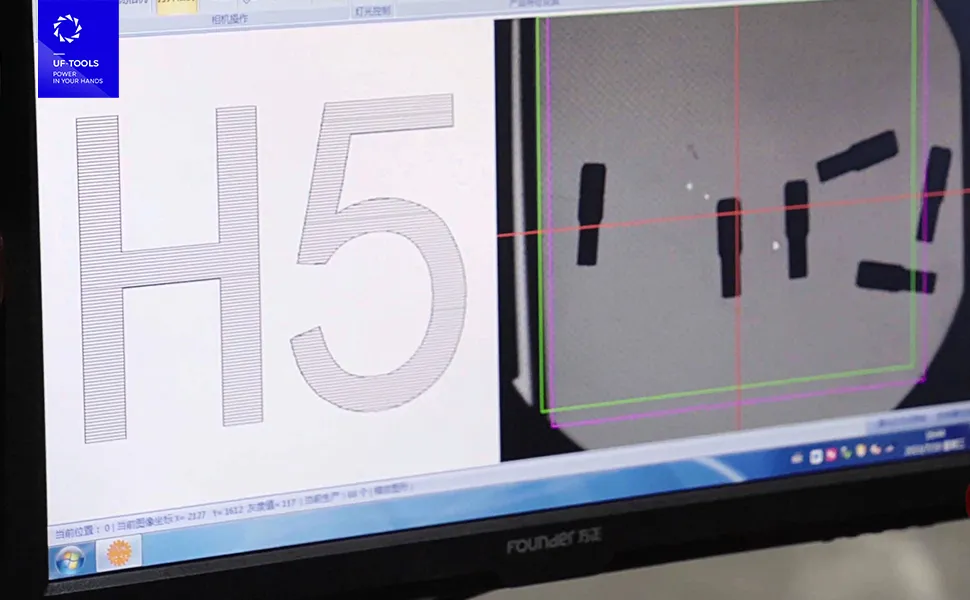

Optical Quality Inspection

Optical quality inspection uses advanced projectors and measuring devices to detect the bit’s shape, angle, and dimensions with high precision.

Heat Treatment

Proper heat treatment improves the bit’s stability and durability. By controlling temperature and cooling speed, the internal structure of the material is modified, enhancing hardness, strength, and wear resistance.

Grinding and Sandblasting

After heat treatment, the bits undergo grinding and sandblasting to make the surface smoother and more refined. This also improves corrosion resistance and extends the product’s lifespan.

Surface Treatment

Surface treatment enhances the product’s appearance and corrosion resistance, and also contributes to its durability and visual appeal.

Laser Engraving

Laser engraving adds unique identification marks. Using laser technology, brand logos, model numbers, or other markings are precisely and clearly etched onto the bits, improving recognition and providing a better user experience.

Magnetizing

Magnetizing is a key process step. By applying a magnetic field, the bits gain magnetic properties, enhancing their ability to attract and control metal screws, making them more efficient and user-friendly.

Final Packaging

At the final stage of production, the screwdriver bits are carefully packaged. This step is not only for neat presentation and sale, but also to protect the product during transportation and storage, ensuring it reaches customers in perfect condition.

Through the above steps, we’ve explored the key processes behind the precise manufacturing of screwdriver bits. This complex and meticulous process ensures that the final product is of high quality and reliable performance, making screwdriver bits an essential and efficient tool.

UFTOOLS offers a wide range of precision screwdriver sets that are perfect for electronics repair, household maintenance, and more. Explore our collection to find the right tool that meets your needs.

About UFTOOLS

As a professional screwdriver manufacturer, UFTOOLS is committed to delivering high-quality precision tools to customers around the world. With strict production standards and advanced processes, we ensure that every screwdriver bit meets the highest level of performance and durability.

Discover more about our screwdriver sets and precision tools at www.uf-tools.com. Whether for home use, professional repair, or distribution opportunities, UFTOOLS is your trusted partner in precision tooling.